|

|

|

|

|

|

|

|

|

|

Automatic Identification & Data Capture AIDC / System Integrations

|

|

|

|

|

|

|

|

|

|

|

|

|

1- Argox | A Subsidiary of Sato Group-Japan

|

|

|

|

|

|

|

|

About Argox

|

|

|

|

|

|

|

|

|

|

1996 is the year Argox was established. Immediately started R&D for barcode printers and entered the market. Argox’s goal is to develop the best technology and meet the demand of international standards.

In January 2012, Argox Information Co., Ltd. became a subsidiary of SATO Japan with a goal of becoming one of the top brands in the world.

ARGOXtake pride with its many achievements in R & D results that include “True Speed”, “Sub-sequence Memory Management”, “Super Historical Control” print control technology, “Multi-language platform, “Super-Alloy high speed” Printing module technology, winning awards like “ID EXPO TOP TEN”, “GOOD DESIGN PRODUCT 1998”, “SYMBOL OF EXCELLENCE WINNER”

In recent years, Argox presence in mainland China has grown rapidly, compelling Argox to set up a branch office in Shanghai, and later in other parts of China, with a goal of dominating the market in the mainland.

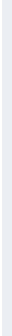

Automation Brain Offers Smart AIDC solutions for diversified industrial applications.

|

|

|

|

|

|

|

|

|

|

|

2- ABPL Smart & Innovative AIDC Solutions For Different Stages Of Industrial Process

|

|

|

|

|

|

|

|

1- Solutions For Manufacturing Area

|

|

|

4- Health-Care & Hospitality Solutions

|

|

|

2- Warehouse Automation

|

|

|

5- Retail Solutions

|

|

|

3- Transportation & Logistics

|

|

|

|

|

|

|

|

|

|

2.1- Solutions For Manufacturing Area

|

|

|

|

A - Product Labeling & Tracking

|

|

|

|

|

|

B - Parts & Material Labeling

|

|

|

|

Correctly identify parts and materials are the key of productivity. Labeling parts and materials is the critical spot affecting locating, dispensing, promptness, and, finally, the productivity of the whole manufacturing facility.

Parts and material ID numbers and descriptions are major information needed in parts label. Either presented in 1D or2D barcode, parts label is the key link between the raw material and all the complicated process involved to turn the raw material into finished product.

Parts and material label can be scanned by Argox full line barcode scanners ( 1D, 2D, corded linked with host computer, or wireless through Bluetooth to work with remote database ) to support parts/material verification requirements at different points in the manufacturing process.

Parts and materials need to be verified against Receiving Order when received. Parts and materials will need to be verified against Picking Order when been picked in the warehouse. Argox mobile computers are ready to serve and fulfill these requirements with different OS, barcode scanning engines, and wireless features to be selected based on customers’ infrastructure status and application requirements.

|

|

|

|

|

|

|

|

Parts & Material Labeling

|

|

|

|

|

|

|

2.2- Warehouse Automation

|

|

|

|

A - Order Picking

|

|

|

|

|

|

B - Parts & Products Check-In/Check-Out

|

|

|

|

|

|

2.3- Transportation & Logistics

|

|

|

|

|

|

2.4- Health-Care & Hospitality Solutions

|

|

|

|

|

|

A - Medical Supply Management

|

|

|

|

|

|

|

Medical Supply Management

|

|

|

|

C - Medicine Dispensing

|

|

|

|

|

|

|

Medicine Dispensing

|

|

|

|

|

|

|

|

B - Record Management

|

|

|

|

|

|

|

Record Management

|

|

|

|

D - Patient Identification

|

|

|

|

|

|

|

Patient Identification

|

|

|

|

|

|

|

|

2.5 - Retailer Solutions

|

|

|

|

|

|

A - Order Picking & Shelving

|

|

|

|

|

|

|

Order Picking & Shelving

|

|

|

|

C - Price Checking

|

|

|

|

|

|

|

Price Checking

|

|

|

|

|

|

|

|

|

|

|

|

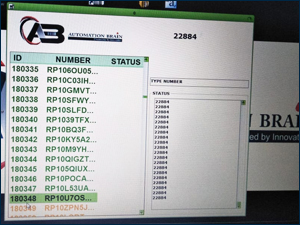

3 - ABPL-System Integration

|

|

|

|

|

|

|

|

ABPL Delivering You The Best Technological Solutions

|

|

|

|

Our teams of systems integration engineers offer a wealth of vendor independent experience drawn from diverse industries. We are system integrator’s who are committed to deliver the best technical solution and customer service throughout the whole life cycle of your system.Our expertise ranges from stand alone applications for PLC, HMI, and specialized software applications developed by our international partners as well as ABPL IT experts .

We have capabilities for integration of our industrial products (like CIJ, LASER, TIJ, DOD, TTO , Metal Detectors , Checkweighers, AIDC products ) with industrial software applications , we can also design customized solutions for specific applications and specific needs.

|

|

|

|

|

|

|

|

Technological Solutions

|

|

|

|

|

|

|

Automation Brain Consumer Promotion (AB-CP)

|

|

|

|

AB-CP , is a customized solution designed by ABPL experts , this is to empower packaging material manufacturers to offer pre-printed CP coding upon diversified packaging materials such as flexible laminates , Card-board cartons, Corrugated cartons, PET bottles , LDPE closures , Special aluminum films , paper films and any challenging substrate AB-CP solution can be modified for specific needs of our prestigious customers, This innovative idea enables both ABPL & packaging manufacturers to join hands for the promotion of customer products .

Standard AB-CP solution is based on Hidden Unique random codes printed on individual primary product packaging , this hidden code is only in the access of consumers who use to send this code to a server for a lucky draw and win a prize , this idea has phenomenally boosted-up market demand for customers products.

|

|

|

|

|

|

|

|

Consumer Promotion

|

|

|

|

|

|

|

|

|

|

|

Automation Brain (Pvt.) Ltd.

|

|

Address

|

:

|

106 D, M.A Johar Town,

Lahore, Punjab

Pakistan

|

|

.

|

.

|

.

|

|

Helpline No

|

:

|

+92 304 111 1613

|

|

.

|

.

|

.

|

|

Email

|

:

|

info@automation-brain.com

|

|

.

|

.

|

.

|

|

Website

|

:

|

www.automation-brain.com

|

|

|

|

|

|

|

|

|

|